FIBERGLASS MESH

Fiberglass alkaline resistant Mesh

Performance

1、High alkaline resistance

Corrosion resistance

2、High tensile strength

Prevent the wall cracking

3、High weatherability

Long service life

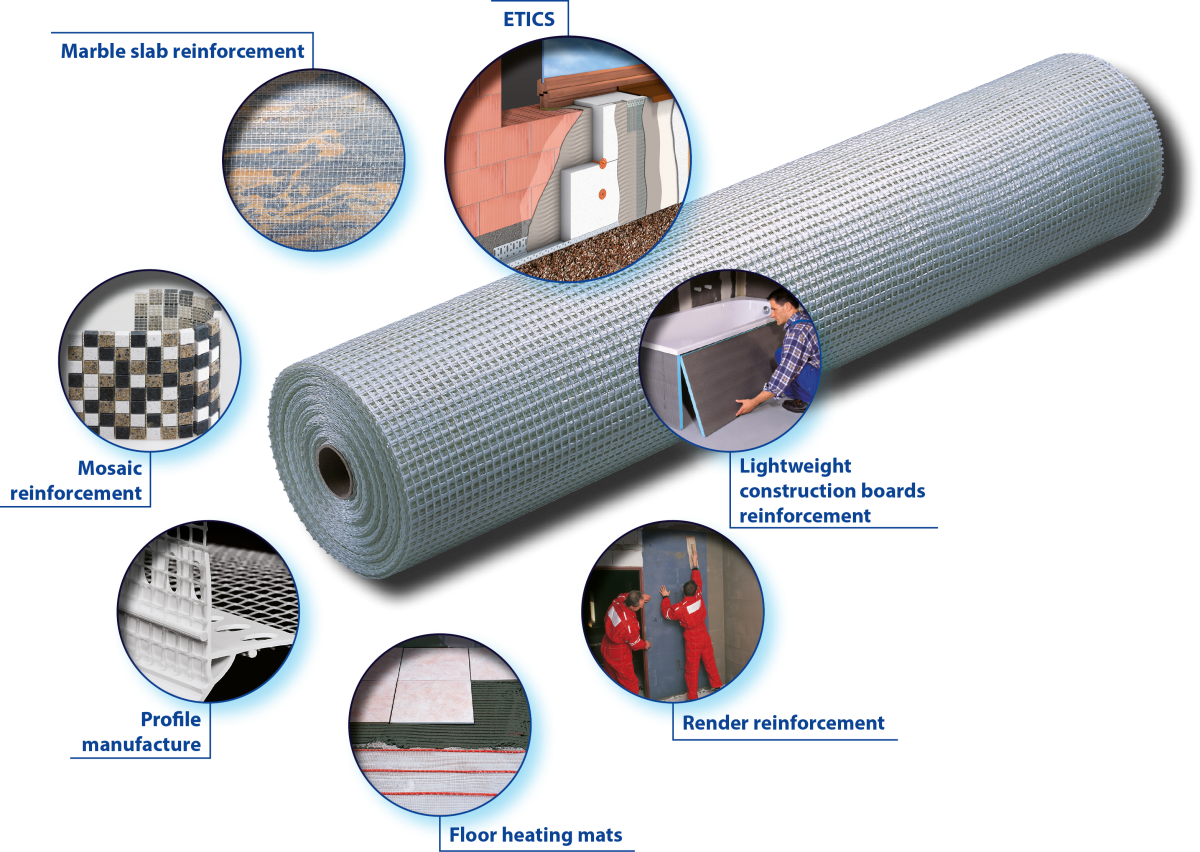

Application

1、 EIFS and Wall Reinforcement

2、Roofing Waterproof

3、Stone & Marble Reinforcement

4、Floor Reinforcement

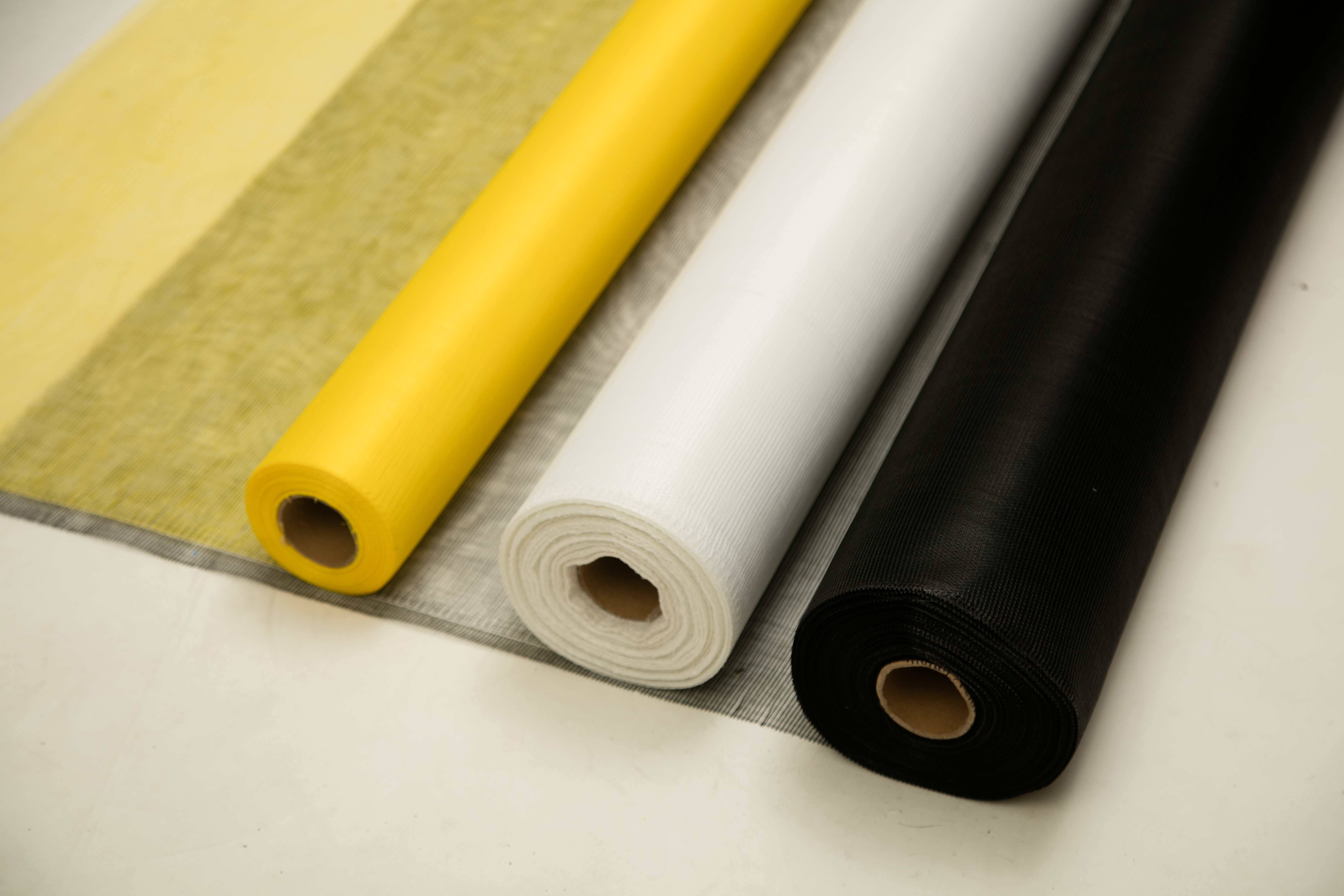

Alkali-resistant fiberglass mesh is woven by fiberglass woven roving as its basis mesh, and then coated by alkali-resistant macromolecule latex. After surface treatment, this alkali-resistant mesh has the features of fine alkaline-resistance, high strength, water-resistance, flexibility, softness and resistance to aging. The product is widely used in wall reinforcement, external wall insulation, roof waterproof, etc. It is an ideal engineering material in construction industry. The product has a variety of colors (white, yellow, green) and a variety of grams (45g, 80g, 120g, 130g, 145g, 160g, and 300g), supporting PVC insulation protector for choice. Special specifications can be customized according to users’ requirements.

The advantages of the alkali-resistant fiberglass mesh

Alkali-resistant fiberglass mesh has significant characteristics: excellent corrosion resistance, good alkali resistance, high tensile strength, high elastic modulus reach 80.4GPa and low elongation at break of 2.4%.

Alkali-resistant mesh with strong elastic modulus and fracture strength is the ideal material that to effectively reinforce cement concrete. It will not deteriorate, not afraid of ultraviolet radiation. And only using a very small amount of mortar coverage will be able to achieve the desired enhancement.

Alkali-resistant fiberglass mesh usages

- Application for EIFS/WALL

Fiberglass alkali resistant mesh is an integral structural material in entire exterior insulation system. Alkali-resistant fiberglass mesh has features of high strength, good adhesion, and can effectively combine with polystyrene board (insulation board) to prevent the corrosion of alkaline materials in the construction materials. It can effectively prevent wall cracking and enhance resistance to pressure as an ideal reinforcing material. - Application for ROOFING WATERPROOF

Because waterproof medium (asphalt) itself has no strength applied in roofing and waterproofing system under external force of seasonal temperature changes, wind and sun, it is inevitable cracking, leakage, would not achieve the effect of waterproof. The addition of a waterproofing membrane containing fiberglass mesh or composite carpet can enhance its wind resistance and tensile strength, so that it can withstand various stress changes without cracking, to obtain a long-term effect of waterproof, avoid roof leakage discomfort and inconvenience to people. - Application for STONE AND MARBLE REINFORCEMENT

Put fiberglass mesh covering on the back of the marble or mosaic. With the fiberglass mesh docile, excellent positioning, the stress of the stone in the construction and application can be uniformly dispersed that to play the role of enhancement and protection. - Application for FLOOR REINFORCEMENT

used globally in building construction. A variety of screed reinforcement solutions exist that are less costly and more effective than steel or polypropylene fibers. High-performance, high-strength products are lightweight and easy to install and use. These innovative, superior alternatives to steel mesh and polypropylene fibers are easy to work with, will not rust or rot and provide increased durability in every cementitious application.